JDSE Ltd

Project:

Decarbonisation of energy is mandatory for a sustainable future and is in reach with the utilisation of hydrogen and bio-methane as fuel sources. In order for hydrogen fuel cells to perform optimally, the fuel source must be free from (or as close to as defined in ISO 14687-2) harmful contaminants, such as H2S and ammonia. However, to measure the levels of these impurities, low and ultra-low concentration calibration gas standards must be manufactured and be kept stable. Unfortunately, over time the trace elements in the reference material are found to decay in the gas cylinders in which they are stored and transported in.

Decarbonisation of energy is mandatory for a sustainable future and is in reach with the utilisation of hydrogen and bio-methane as fuel sources. In order for hydrogen fuel cells to perform optimally, the fuel source must be free from (or as close to as defined in ISO 14687-2) harmful contaminants, such as H2S and ammonia. However, to measure the levels of these impurities, low and ultra-low concentration calibration gas standards must be manufactured and be kept stable. Unfortunately, over time the trace elements in the reference material are found to decay in the gas cylinders in which they are stored and transported in.

This project seeks to understand why the gas standards are unstable when under regular conditions and then prevent sample degradation by passivating gas cylinders with novel coatings.

This technology could also be used elsewhere, primarily in the containment of samples of hydrogen fuel for accurate measurement of impurities after said standards have been used for calibration.

SEND:

A key aspect of SEND is to work alongside other projects on the University campus to reduce the Carbon Dioxide CO2 emissions. One way the University is working to achieve this is via the use of hydrogen with natural gas. This project can help to improve the storage and transportation of hydrogen.

Project progress (June 2019):

- Completed comprehensive literature review.

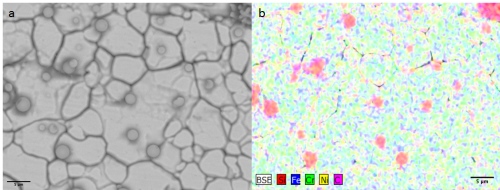

- Analysed a number of existing coatings/treatments (Luxfer, electropolished, SilcoNert, Experis).

- Next steps are to analyse more samples and to design and trial passivation ideas.

Business Contact(s): Jeremy Knight

Keele Graduate Researcher: Luke Latham-Wheawall

Keele Academic(s): Dr Richard Darton; Dr Peter Matthews